Soft Cost Reductions for Solar

By James Ferguson

Our research team seeks to implement a residential solar employee benefits program at Duke makes solar more accessible to Duke Employees. One key goal of this program is to reduce the cost of solar for participants in the program. A 2013 reportfrom Rocky Mountain Institute (RMI) sheds light on an area that can help us achieve this: soft costs reductions. Solar “soft costs” refer to any non-hardware expenses that go into a solar installation. These include installation processes such as planning, travel, unloading, racking & mounting, installing the inverter, electrical wiring, and daily construction clean up (Morris et al. 2013). In order to bring down overall cost, we must bring down soft costs. In order to bring down soft costs, installation processes must be made more efficient. Germany has done just that.

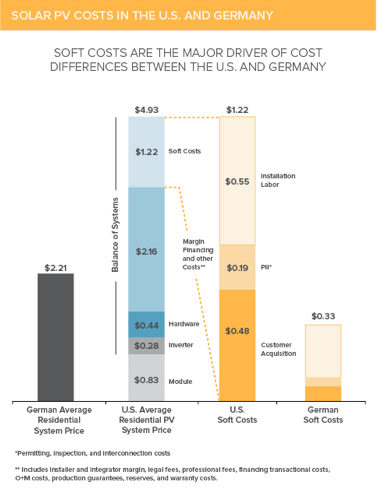

Germany’s average installed price for solar in 2013 was a full $2.72/W less expensive than that of the United States (2013). The difference in soft costs drives this; RMI reports that in 2013 soft costs made up 80% of the difference between American and German overall cost of residential solar.

A complicated landscape of permitting, inspection and interconnection across thousands of jurisdictions in the United States makes the installation process frustratingly inefficient. Efforts to streamline these processes and the installation process itself can drive down soft costs, which in 2013 made up nearly 70% of total cost ($4.93/W) of U.S. residential solar. The United States thus has huge potential for reductions here.

RMI outlines specific measures, with a focus on installation labor, to lower soft costs. The options vary in degree of difficulty to implement and impact on cost reduction:

Those that are easiest to implement include:

- One-day installations help save a significant amount of time and money. Completing the install in a single day minimizes built-in costs associated with each day’s work.

- On-ground rail prep means less time wasted on the pitch of the roof, setting and placing the rails for the solar panels. Completing this on the ground saves time and money.

- Rail-less racking uses integrative racking design free of rails. The hassle of rails is eliminated, allowing for even faster completion of the installation process.

- Conduit redesign calls for flexible material that is pre-wired. This eliminates the time-sink of feeding wire through the conduit and can quicken the process of wiring the solar system.

While RMI’s suggestions are constructive, there are several challenges working against them. Lack of general knowledge about best practices, something RMI’s report aims to combat, precludes them from taking place. Sparse knowledge sharing between installers in order to maintain competitive advantage also contributes to slow progress (K.Calhoun interview from Thill, 2013). Besides general know-how and knowledge sharing, RMI alludes to some systemic challenges U.S. installers face that impede soft cost reductions. These include policies regarding extensive inspection requirements, conduit requirements, and stringent safety regulations among others (Morris et al. 2013). A lack of standardization in both product and installation process also prevents soft cost reductions (e.g. lack of: universal racking bases, specialized crews, equipment lifts, etc.) (2013). In order to move forward, installers must partner with others to overcome such challenges or find other ways to reduce soft costs.

Our research team has ample opportunity to find soft cost reductions and our proposed program is designed to maximize them. To start, we largely remove the soft cost associated with customer acquisition (marketing, business development, etc.) by introducing university employees, our target audience, directly to installers. We will also seek out installers that use the best practices highlighted by RMI, as these can reduce soft costs. By asking installers about their processes we can make sure we choose the most efficient, lowest-cost solar available. We may also be able to encourage them to improve their installation practices. Reducing soft costs can benefit all stakeholders; the solar installer decreases its operating costs, making it more competitive against other installers, and customers see the benefit through reduced price. This describes the win-win that has occurred in Germany, and that we are striving to achieve here at Duke.

References

Morris, J., Calhoun, K., Goodman, J., and Seif, D. 2013. Reducing solar PV soft costs: A focus on installation labor. Rocky Mountain Institute: Boulder, CO. Available online at: www.rmi.org/Knowledge-Center/Library/2013-16_SimpleBoSRpt. All figures and graphs are from this report.

Thill, S. 2013. Reducing solar soft costs means tackling labor expenses. Solar Energy News. Available online at: http://solarenergy.net/News/reducing-solar-soft-costs-means-tackling-lab....